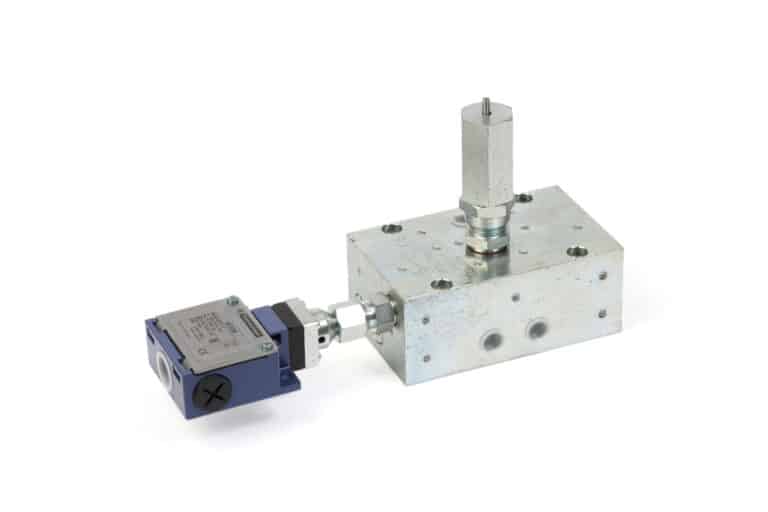

Series 2210XXX

Overpressure reverser C12

It is used for switching lines into double line lubrication systems of grease or oil

PDF files

Features

- Robust body made of steel

- External zinc-plated protection

- Different possibilities of control

- Adjustable pressure range

Description

The overpressure reversers are especially useful equipment in double grease lines to have automated alternate operation of both lines. The equipment automatically pressurizes or relieves the lubricant flow from one line to the other depending on the predetermined pressure.

Design and operating principle

This overpressure reverser is mechanically actuated and specially designed for double line systems of medium length. Overpressure reverser works very similar to a two ways- two ports valve. If the pressure in the work line reaches the set pressure, an internal overpressure valve will open and command a piston to actuate against the other two pistons, one of them will switch the work line.

Installation

To ensure a correct operation, the location of the overpressure reverser in the installation must be at the beginning of the grease line, at the pump outlet.

Specifications

| Flow | 12 kg/h |

| Maximum working pressure | 300 bar |

| Minimum working pressure | 40 bar |

| Inlet connection | G 3/8 female |

| Outlet connection | G 1/4 female |

| Return connection | G 1/4 female |

| Mounting position | Variable |

| Body material | Steel EN10087 – 11SMnPb30 zinc-plated |

| Weight | 4,4 kg |

| Dimensions | 130x80x55 mm |

| Qualities | Electroplated coating of zinc ISO 2081 – Fe/Zn12/A |

Order information

| ADD CODE DEPENDING ON ASSEMBLY | |||

| C12- | X | -XX | |

| Operational control | |||

| Visual | V | ||

| Limit switch | I | ||

| Inductive proximity sensor | D | ||

| Special code | |||

| For non-standard elements | -XX | ||

Other products

We will get back to you within 24 hours

Do you have any questions? Are you ready to buy? Your Nortek assistant is ready to help you

Success stories

We are your reliable partner to make everything flow and nothing stands still.

Leave the fluid management of all your machines in our hands so that they always work at 100%, increase their performance and extend their service life. It’s time to stop worrying about the performance of your machinery.

Discover how our solutions have delivered great results