Reduction of stoppages due to bearing failures and improvement of environmental conditions in an ArcelorMittal rolling mill

- CUSTOMER

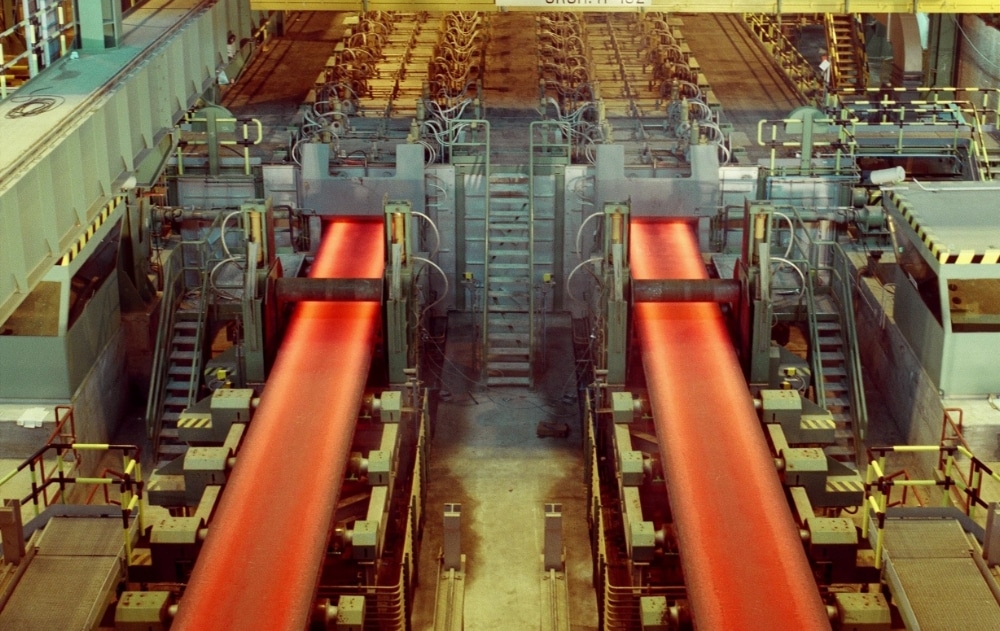

ArcelorMittal - FINAL DESTINATION

Temper Mill Aviles (Asturias, Spain) - PLANT TYPE

Cold rolling tandem mill - YEAR

2015

The challenge

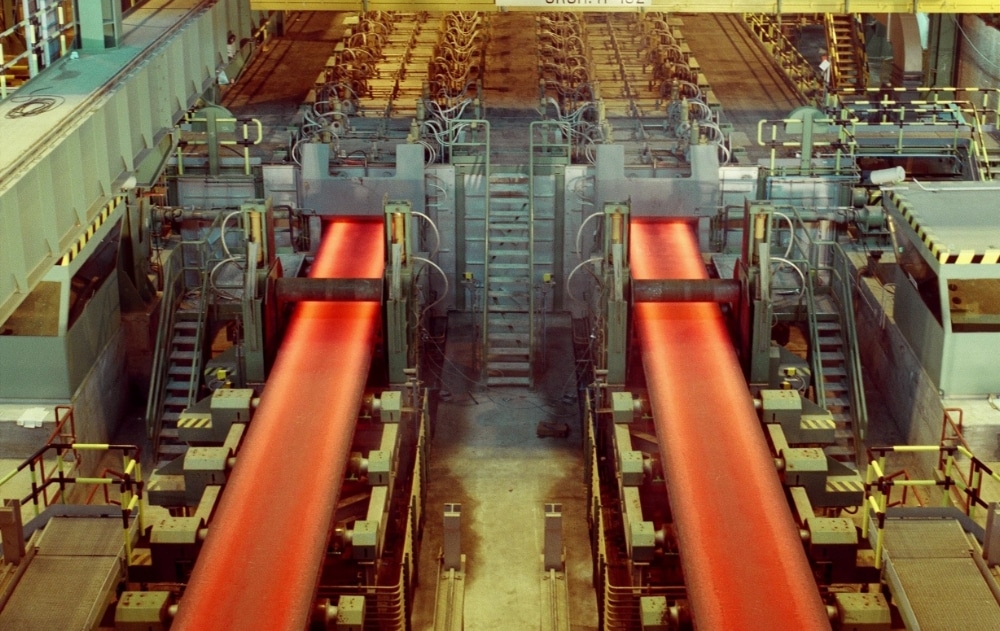

The customer was using oil mist to lubricate the rolling mill bearings, leading to a number of issues:

- Work safety problems. A large amount of oil was dispersed around the entire train, with the risk of creating dangerous situations for the workers.

- Environmental problems derived precisely from oil contamination.

- Production and reliability problems due to continuous bearing breaks due to the low efficiency of the mist lubrication system.

The solution

NORTEK proposed to replace the old oil mist system with an air-oil lubrication system, the result of its technological development. This system allows:

- Work with very high viscosity oils, increasing the resistance of the lubricating film in slow-moving bearings with high loads.

- Check the amount of oil injected into the bearings (in case of failure, the system issues an alarm).

- Increase the size of the oil drop, avoiding leaks into the atmosphere and thus reducing the risk of environmental contamination.

One of the most complex aspects of the project was the need to create an automatic connection system in the chocks on the engine side. This was achieved through a bespoke design of a mobile connection system with electrical confirmation.

The result

With the current system, oil contamination has been reduced, improving the work environment and eliminating environmental contamination. In terms of performance, it has been possible to increase the life of the bearings by 600%.