Series Serie 420XXXX

Filter element

PDF files

420XXXX Series

Features

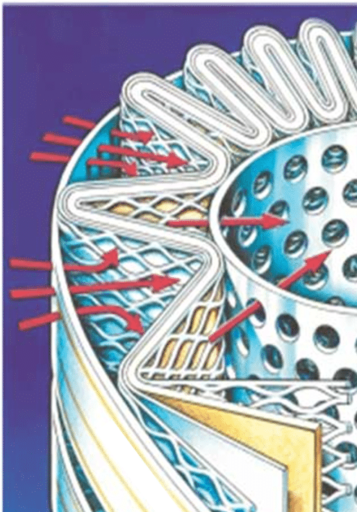

- An external helical wrap for elements with fiberglass nonwoven fabric firmly binds each pleat for uniform and rigid pleat spacing. This minimizes pleat flexing and possible damage to the filter element, offering flow protection even under severe cold start or pressure overload conditions, providing reliable performance.

- The plastic structure of the ends incorporates flow channels facilitating oil circulation, thus minimizing the effects of pressure drop and maintenance costs by increasing the fatigue cycles of the element. A bypass valve integrated in the filter protects the element when a certain differential pressure is exceeded.

- The choice of the appropriate filter media depends on the type of application. Fiberglass, polyester, cellulose, cellulose, metal fiber and stainless steel mesh media are used for hydraulic applications.

- Non-woven fiberglass cloth – They have a high dirt absorption capacity and an excellent degree of separation (3-25µm) thanks to their labyrinth structure.

- Polyester mat – 100% thermally bonded polyester fiber filter material offering high resistance to pressure differentials, high dirt absorption capacity and excellent separation efficiency (3-25µm) with low flow resistance, good chemical and wear resistance.

- Filter paper – filter material made of cellulose fibers with special impregnation, an economical variant with a good absorption capacity and a degree of separation (10-50µm). Not suitable for aqueous media.

- Stainless steel nonwoven – Filter material consisting of sintered metal fibers with labyrinth structure for depth filtration, high dirt absorption capacity and excellent separation rate (3-25µm) with low flow resistance, good chemical and thermal resistance.

- Stainless steel wire cloth – Filter material made of woven wire mesh (square or braided) in 1.4301 or 1.4305 steel for surface filtration, offering low flow resistance and a degree of separation (10-1000µm), excellent chemical and thermal resistance.

- The O-ring seal configurable in different materials (NBR, EPDM, Teflon) according to the applications, together with the strength of the end caps as part of the filter housing, make up this competitive element, reducing disposal and maintenance costs.

Description

Nortek filters incorporate state-of-the-art design technology, which by means of a pleated support system and the arrangement in the structure of the elements that compose it, achieves unsurpassed strength, performance and service life.

Design and principle of operation

Both the design and the composition of the elements are designed to facilitate the circulation of the oil through the filter, minimizing load losses and retaining contaminants as they pass through the filter elements according to the degree of filtration to be obtained (Beta Ratio “β”: The number of particles entering the filter, divided by the number of particles leaving the filter).

The effectiveness of the filter element in controlling contaminants depends on its design and its sensitivity to any unstable operating conditions that may stress and damage the filter element.

Installation

In the installation of these filter elements, the type of process must be taken into account, in order to adapt the element according to the needs and in the most efficient way possible.

Applications

- Nortek 420XXXX series filters are suitable for hydraulic systems, lubrication of mechanisms and fluid control. They are return filters that are installed in the oil reservoir and filter the hydraulic oil before it returns to the oil reservoir. This ensures that the dirt that appears on the components does not reach the reservoir, they work under low pressure and temperature conditions and their action preserves the useful life of both the equipment components and the hydraulic fluid.

Specifications

| Especificaciones | |

| Pérdida de carga | (ver gráficos de curvas características de caudal) |

| Presión de colapso | 10…25 bar (145…362 psi), según norma ISO 2941 ( ANSI B93.25 ) |

| Compatibilidad con fluidos | Derivados del petróleo, refrigerantes, emulsiones de aceite en agua.

Según norma ISO 2943 ( ANSI B93.23 ) |

| Resistencia de carga de la tapa terminal | Según norma ISO 3723 |

| Resistencia a fatiga | Según norma ISO 3724 ( ANSI B93.24 ) |

| Rango de temperatura | 0 – 107ºC ( 0 – 225ºF ) para la mayoría de los fluidos hidráulicos |

| 0 – 65ºC ( 0 – 150ºF ) para refrigerantes | |

| 0 – 93ºC ( 0 – 200ºF ) para derivados del petróleo | |

| Diámetro de la boquilla | 60mm ÷ 143mm ( 2,36” ÷ 5,63” ) |

| Prueba de rendimiento Multi-pass | Según norma ISO 16889 |

| Prueba del método de burbuja | Según norma ISO 2942 |

| Curvas características de caudal | Según norma ISO 3968 |

| Juntas | NBR – EPDM – Teflón |

Order information

| Especificaciones | Referencia |

| Modelo cartucho | 420 A B C D |

| Según tamaño – A (ver tabla en Plano dimensional) | |

| 07 | |

| 09 | |

| 13 | |

| 16 | |

| 20 | |

| 25 | |

| 30 | |

| 60 | |

| Según filtración – B Micron | |

| 3 | 1 |

| 5 | 2 |

| 10 | 3 |

| 20 | 4 |

| 25 | 5 |

| 50 | 6 |

| 100 | 7 |

| 200 | 8 |

| 40 | 9 |

| 60 | 0 |

| 80 | 1A |

| Según material – C Tipo | |

| Fibra de vidrio para aceite | 1 |

| Fibra para agua | 2 |

| Fibra para aceite y agua | 3 |

| Papel Ø 114mm | 4 |

| Malla inoxidable | 5 |

| Fibra inoxidable | 6 |

| Papel Ø 95,5mm | 7 |

| Según material juntas –D Material | |

| NBR | 1 |

| EPDM | 2 |

| TEFLON | 3 |

| 42013341 | Cartucho tamaño 13 Filtración 100 micron Fabricado en papel Ø 114mm Juntas NBR |

Other products

We will get back to you within 24 hours

Do you have any questions? Are you ready to buy? Your Nortek assistant is ready to help you

Success stories

We are your reliable partner to make everything flow and nothing stands still.

Leave the fluid management of all your machines in our hands so that they always work at 100%, increase their performance and extend their service life. It’s time to stop worrying about the performance of your machinery.

Discover how our solutions have delivered great results