Series Serie 269412X

Filter element

PDF files

Series 269412X

Features

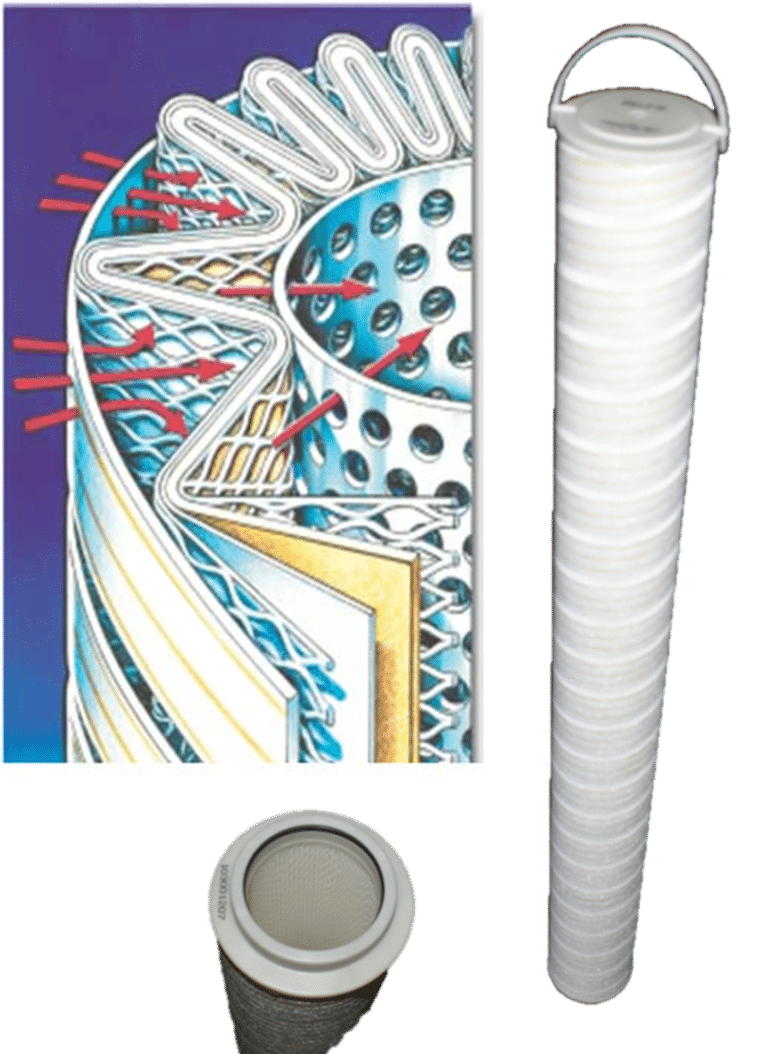

- An outer helical wrap tightly bonds to each pleat for uniform, rigid pleat spacing. This minimizes bending of the pleats and possible damage to the filter element, even under severe conditions of cold start or pressure overload, providing reliable performance.

- The plastic structure of the ends incorporate flow channels facilitating oil circulation, thus minimizing the effects of pressure drop and maintenance costs by increasing element fatigue cycles.

- The filter element is formed by inert inorganic fibers of extremely small diameter allowing more pores per unit area, securely attached to a structure of fixed pores and conical, this improved design obtain a high efficiency of elimination of particles during the useful life of the element, instead of the traditional uniform pore, which is quickly covered when the grime covers the outer surface of the filter media. The conical pores separate the particles through their full depth, for maximum dirt holding capacity, constant performance and long life.

- O-ring seals, corrosion resistant end caps and a rugged metal inner core complete the element structure. This element have no metal components. End caps are reinforced polymer and the core is part of the filter housing. Thus the element is lightweight (60% lighter than traditional designs), crushable, and incinerable.

Aplication

The Nortek filters are suitable for hydraulic systems, lubrication mechanisms and fluid control, under conditions of high pressure and temperature, where the oil is full of contaminants and dust, allowing to preserve the useful life of both the components of the equipment and of hydraulic fluid.

Design and operating principle

Both the design and the composition of the elements, are thought-out improving the circulation of the oil through the filter, minimizing the loss of charge and retaining contaminants as it passes through the filtering elements according to the degree of filtration you want to obtain (Beta Ratio “β”: The number of incoming particles in the filter, divided by the number of particles leaving the filter).

The effectiveness of the filter element in the control of contaminants depends on its design and its sensitivity to any unstable operating condition, which may stress and damage the filter element.

Description

High performance Nortek filters incorporate state-of-the-art design technology, including a unique “helical wrap” pleat support system and composite element structure for unsurpassed strength, performance and service life. The result is a cost-effective solution clearly superior to traditional filter designs.

Installation

In the installation of these filter elements, the type of process must be taken into account, in order to adapt the element according to the needs and the most efficient way possible.

Specifications

| Specifications | |

| Pressure drop | 4 bar (58 psid) |

| Collapse Pressure | 10,3 bar (150 psi), according to standard ISO 2941 ( ANSI B93.25 ) |

| Fluid Compatibility | Petroleum oils, coolants, water-oil emulsions

According to standard ISO 2943 ( ANSI B93.23 ) |

| Flow Fatigue | According to standard ISO 3724 ( ANSI B93.24 ) |

| Temperature Range | 0 – 107ºC ( 0 – 225ºF ) para la mayoría de los fluidos hidráulicos |

| 0 – 65ºC ( 0 – 150ºF ) para refrigerantes | |

| 0 – 93ºC ( 0 – 200ºF ) para derivados del petróleo | |

| Diameter of nozzle | 55,55mm ÷ 55,49mm ( 2,187” ÷ 2,187” ) |

| Performance test Multi-pass | According to standard ISO 16889 |

| Bubble-point test method | According to standard ISO 2942 |

| Evaluation of differential pressure versus flow | According to standard ISO 3668 |

| O-rings | NBR – Nitrile |

Order information

| Specifications | Reference |

| Filter 12 microns, beta 1000 Weigth: 3,2 Kg | 2694124 |

| Filter 22 microns, beta 1000 Weigth: 3,2 Kg | 2694125 |

Other products

We will get back to you within 24 hours

Do you have any questions? Are you ready to buy? Your Nortek assistant is ready to help you

Success stories

We are your reliable partner to make everything flow and nothing stands still.

Leave the fluid management of all your machines in our hands so that they always work at 100%, increase their performance and extend their service life. It’s time to stop worrying about the performance of your machinery.

Discover how our solutions have delivered great results