Series Serie 3238X33

Hydraulic dosing unit 15 cm3

PDF files

Serie 3238X33

Features

- Block design to avoid leakage

- High performance

- Robust body in EN 10087-11SMnPb30

- Adjustable flow rate

Aplication

These dispensers are installed in hydraulic lubrication lines and are intended for installations with a large number of lubrication points and/or long distances.

Installations in the iron and steel industry, cement or paper mills can use this type of dispenser with a high guarantee of precise lubrication.

Design and operating principle

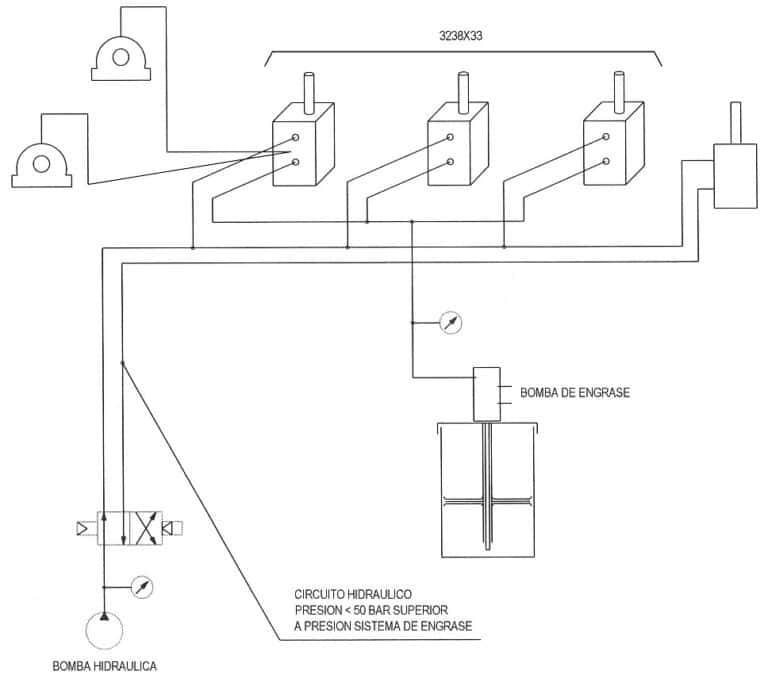

This dispenser is designed to be operated by a pump or hydraulic device.

The equipment consists of an oil inlet, a grease inlet and two grease outlets, which can be joined together to double the flow output by means of a connecting device (see accessories).

Each metering unit consists of a servo piston and a servo, whose movement is controlled by hydraulic oil. The grease inlet has a constant pressure and the piston movements are controlled by the hydraulic oil inlet, pressurization or depressurization of the line.

Description

Hydraulic dispensers are lubrication elements designed for two simultaneous supply lines, the movement is given by the hydraulic line that pressurizes and depressurizes alternating lubrication cycles, thus dosing a quantity of lubricant in each cycle.

Installation

They are placed in double lines along the entire length of the installation in the areas closest to the greasing zone. The number of dispensers to be installed depends on the length of the installation and the points to be greased.

For correct operation it is recommended to maintain a pressure difference between the hydraulic oil and the lubricating grease of 50 bar.

Specifications

| No. of outlets | De 2 a 4 salidas |

| Output flow per injection | 15 cm3 |

| Minimum oil working pressure | 50 bar |

| Minimum working pressure grease | 100 bar |

| Maximum oil working pressure | 300 bar |

| Maximum working pressure grease | 240 bar |

| Recommended oil working pressure | 200 bar |

| Recommended grease working pressure | 150 bar |

| Connections | 1/4″ bsp |

| Qualities | Cincado ISO 2081 – Fe/Zn12/A |

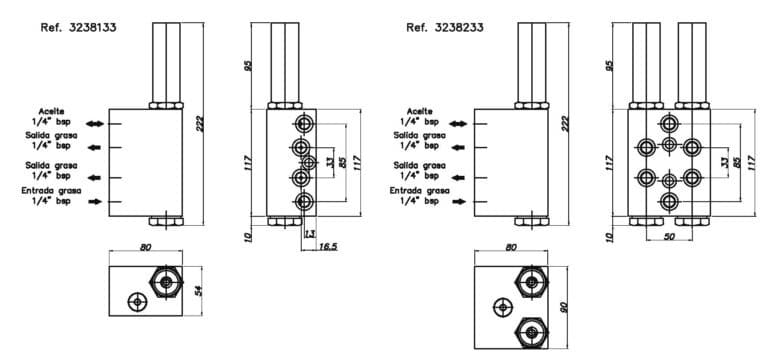

Dimensional drawing

Order information

The standard supply is a single turret with body in EN 10087-11SMnPb30 with zinc plating according to ISO 2081 – Fe/Zn12/A, methacrylate cap, NBR seals and body in AºCº.

| Specifications | Weight | Reference |

| 2 salidas ( 1+1 ) | 5 kg | 3238133 |

| 4 salidas ( 2+2 ) | 8 kg | 3238233 |

Accesories

| Specifications | Referencia |

| Unior outlets | 3238010 |

We will get back to you within 24 hours

Do you have any questions? Are you ready to buy? Your Nortek assistant is ready to help you

Success stories

We are your reliable partner to make everything flow and nothing stands still.

Leave the fluid management of all your machines in our hands so that they always work at 100%, increase their performance and extend their service life. It’s time to stop worrying about the performance of your machinery.

Discover how our solutions have delivered great results