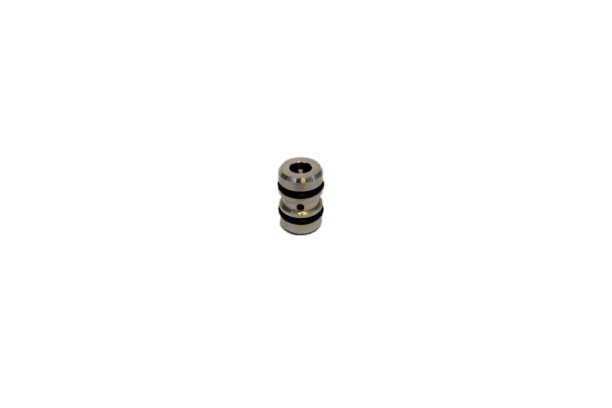

Series Serie 4116955

Divinor Ø10

PDF files

Serie 4116955

Features

- High greasing precision.

- Ease of assembly.

- Simplicity of installation.

- Reduced space

Description

These flow dividers, patented as “Divinor” by Nortek, have the task of distributing the air-oil over several lubrication points without using several lubrication points without using mechanical means.

Although they can be used in any type of industry, they have been developed for applications in the steel industry, especially in applications, especially in rolling mill blast furnaces.

The main feature lies in its 50/50 distribution because it is specially designed for small spaces with difficult lubrication.

reduced spaces with difficulty of lubrication.

Applications

Lubrication of the rolling bearings in rolling mill chocks (previous machining it is necessary).

Design and operating principle

The flow accesses the interior of the “Divinor” through the inlet, entering by the internal divider which is in charge of distributing the flow through both outlets depending on the holes made in both outlets, due to its grooved profile developed by Nortek causes division to be done accurately by both outputs

Installation

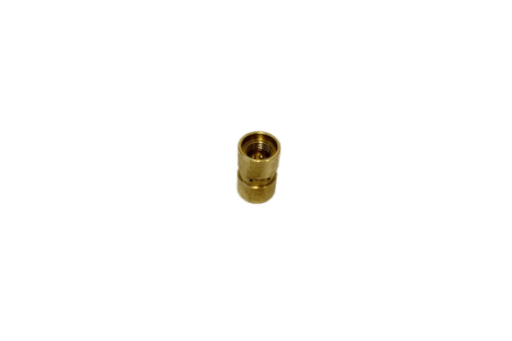

It is made by means of a longitudinal hole recommended by Nortek of Ø25 H11 made in the chock in an obstacle-free area with a side of the chock threaded at 1 ”bsp as standard (optionally M30x1.5) and the another side a lubrication hole to seal as well as some drill holes towards the bearing and seals. On the opposite side to the reten to seal, a ¼” bsp Nortek inlet system is placed. Internally, as many “Divinores” will be placed as necessary, placing threaded intermediate extensions as needed. The drill holes are plugged on the outside

Specifications

| Material | EN 10088-2/3/4; EN 10216-5 – X5CrNiMo17-12-2 |

| Peso | 0,1 kg |

Order information

| Especificaciones | Referencia |

| Divinor Ø10 | 4116955 |

Other products

We will get back to you within 24 hours

Do you have any questions? Are you ready to buy? Your Nortek assistant is ready to help you

Success stories

We are your reliable partner to make everything flow and nothing stands still.

Leave the fluid management of all your machines in our hands so that they always work at 100%, increase their performance and extend their service life. It’s time to stop worrying about the performance of your machinery.

Discover how our solutions have delivered great results