-

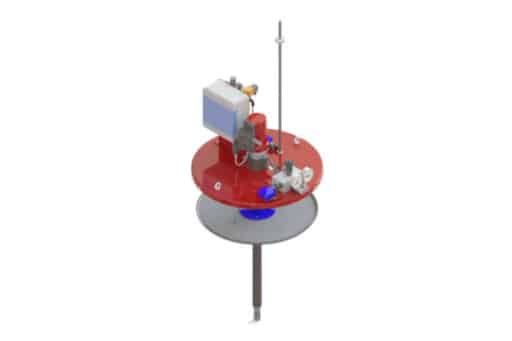

M12 monobloc pump unit

19XXXXXXX series

Specifications

- One-piece system

- Wide range of configurations to suit customer flow requirements.

- Configurable with terminal box or electrical panel

Description

One-piece lubrication system prepared for centralized lubrication control.

Consisting of a Nortek 1029700 series B12 automatic pump prepared on a baseplate to operate in single and double line with medium to high efficiency. The system can be configured by means of a progressive distributor or an inverter. An electrical signal can be added to the output equipment to control system operation. A panel or terminal box can also be installed according to customer requirements.

.

Design and operating principle

These switchboards are designed for intermittent or continuous use.

The operating principle is determined by whether the switchgear is a single or double line.

In the single-line configuration, the lubricant is pumped by the motorized pump and fed via a main line to the metering element. It is then distributed to the lubrication points according to the customer’s installation. Nortek offers dosing elements with a wide range of flow rates, enabling the lubrication system to be optimally adapted to customer requirements.

In the double-line configuration, lubricant is fed to the dosing element via two pipes, alternately pressurized and depressurized. It is then distributed to the lubrication points according to the customer’s installation. It can also be combined with progressive systems.

Installation

This pump must be installed in a location offering sufficient space for maintenance.

The system is prepared with holes in the base plate to anchor it to the ground, in order to avoid possible vibrations and misalignment of the pump.

Nortek recommends ground anchoring in a protected area, away from shocks and passageways.

Specifications

| Recommended operating pressure | 250 bar | ||

| Maximum operating pressure | 400 bar | ||

| Flow rate | De 1,43 kg/h et 12,3 kg/h | ||

| Approximate average weight | 60 kg |

Order information

Pump model

| 1 9 X X X X X X X | ||

| Reduction | ||

| 1: 30 2 | ||

| 1: 7,5 4 | ||

| 1: 12 6 | ||

| 1: 55 7 | ||

| Tank | ||

| Tank 10 L 0 | ||

| Tank 20 L 1 | ||

| Tank 40 L 2 | ||

| Levels | ||

| Radar 0-10 V 0 | ||

| Radar 4-20 mA 1 | ||

| Maximum 2 | ||

| Minimum 3 | ||

| Minimum-minimum 4 | ||

| Minimum and maximum 5 | ||

| Minimum-minimum – Minimum and maximum 6 | ||

| Motor | ||

| Motor 0,18 kW 0 | ||

| Motor 0,25 kW 1 | ||

| Motor 0,37 kW 2 | ||

| Eloectricity | ||

| Not wired 00 | ||

| Terminal box 01 | ||

| Electrical panel for radar 50 | ||

| Electrical panel for remote end-of-line 52 | ||

| Voltage | ||

| 380 V 50 Hz A | ||

| 400 V 50 Hz B | ||

| 415 V 50 Hz C | ||

| 440 V 60 Hz D | ||

| 460 V 60 Hz E | ||

| 480 V 60 Hz F | ||

| Output control | ||

| No control A | ||

| Inverter and visual control E | ||

| Inverter and microcontroller control F | ||

| Changeover and sensor control G | ||

Other products

We will get back to you within 24 hours

Do you have any questions? Are you ready to buy? Your Nortek assistant is ready to help you

Success stories

We are your reliable partner to make everything flow and nothing stands still.

Leave the fluid management of all your machines in our hands so that they always work at 100%, increase their performance and extend their service life. It’s time to stop worrying about the performance of your machinery.

Discover how our solutions have delivered great results