AIROTEK: Nortek Air-Oil Solutions

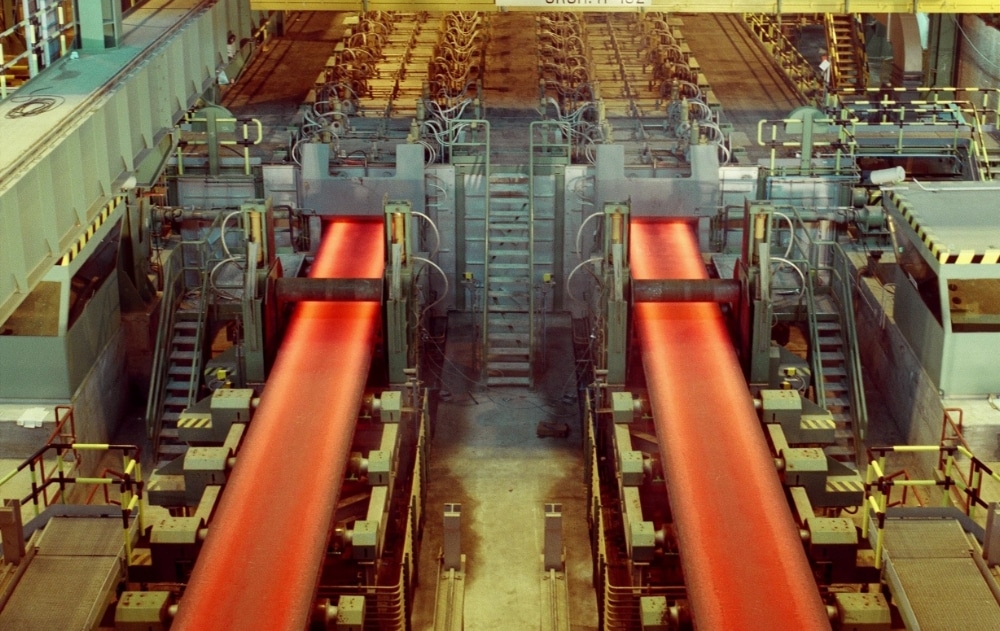

The air-oil lubrication solution for your rolling mill that pays for itself.

Nortek’s air-oil lubrication solutions offer precise, clean and continuous lubricant delivery, eliminating the excesses and typical problems associated with grease, such as accumulation, overheating and premature component wear.

Thanks to their pulse-controlled feeding and precise oil atomisation, these systems keep your bearings and mechanisms in optimal condition, even in high-speed or high-temperature applications. Furthermore, by supplying oil in controlled, measured doses, they ensure a constant lubricating film that reduces friction and improves heat transfer, extending the service life of your equipment.

AIROTEK technology not only minimises environmental pollution and maintenance requirements, but also allows each lubrication cycle to be monitored with complete visibility, ensuring stable operation and freedom from unexpected failures. For industrial processes where reliability and operational efficiency are critical, this solution becomes a strategic process that optimises performance, reduces costs and increases machine availability.

Are you interested in AIROTEK?

Fill in this form to receive detailed information directly from our expert technicians.

Polígono Los Leones 37

50298 Pinseque

Zaragoza

+34 976 656 999

nortek@nortek.es

Why should you stop lubricating bearings with grease?

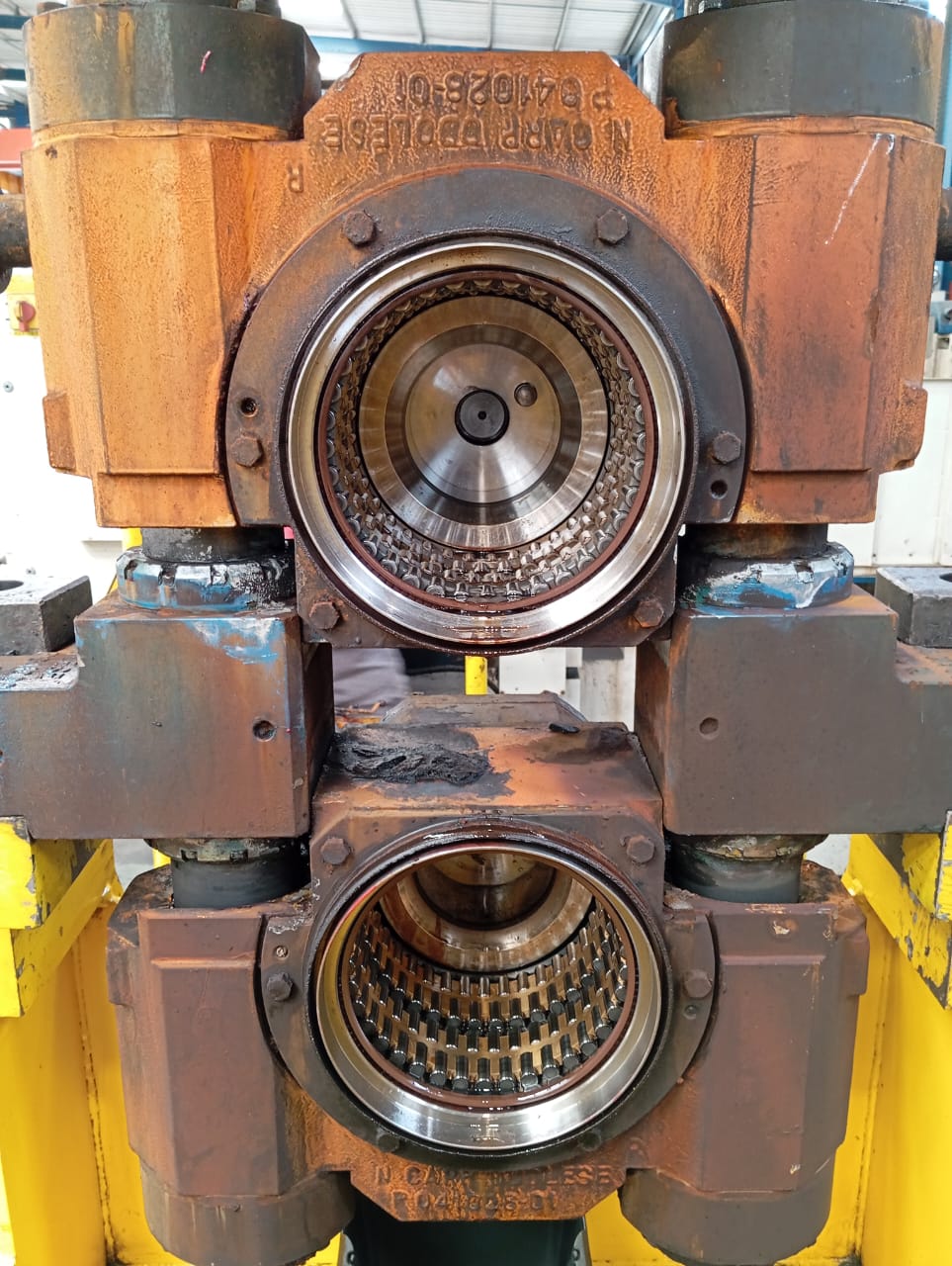

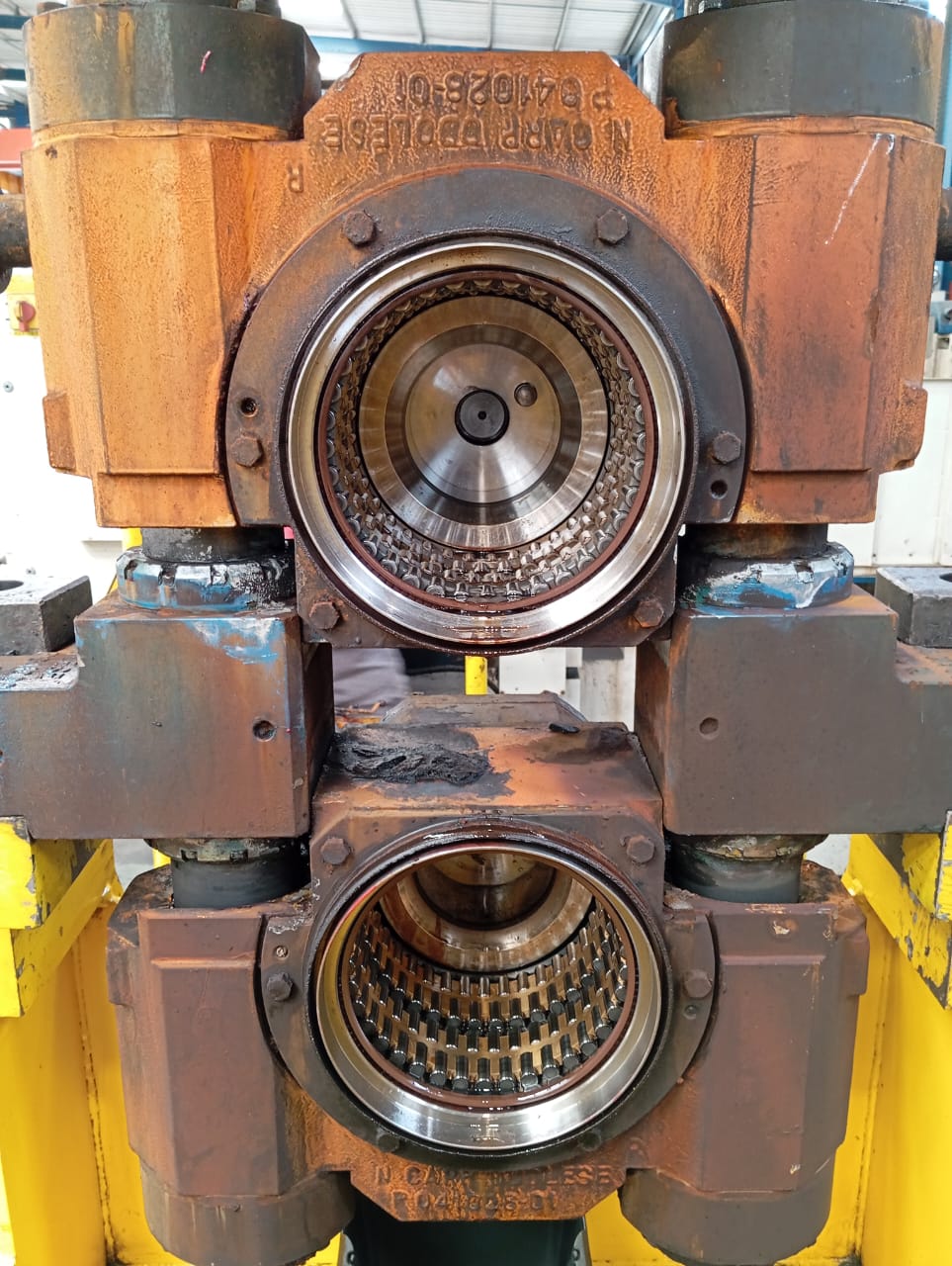

For years, grease has been the primary choice for bearing lubrication, but its use involves limitations that can affect the efficiency and reliability of industrial processes.

As it is a semi-solid lubricant, its heat dissipation capacity is lower, which increases the risk of overheating and reduces the bearing’s service life. Furthermore, its viscosity makes it difficult to control the amount applied precisely, leading to excess or insufficient application, which causes premature wear, unnecessary consumption and possible failures.

Grease also tends to become contaminated and degrade more easily, losing properties and creating the need for more frequent maintenance. For these reasons, upgrading to cleaner, more controllable and efficient lubrication systems has become a strategic decision to optimise operation and extend the life of equipment.

- Accumulation of grease

- High maintenance costs

- Inefficient lubricant use

Precise, controllable, adaptable and clean lubrication.

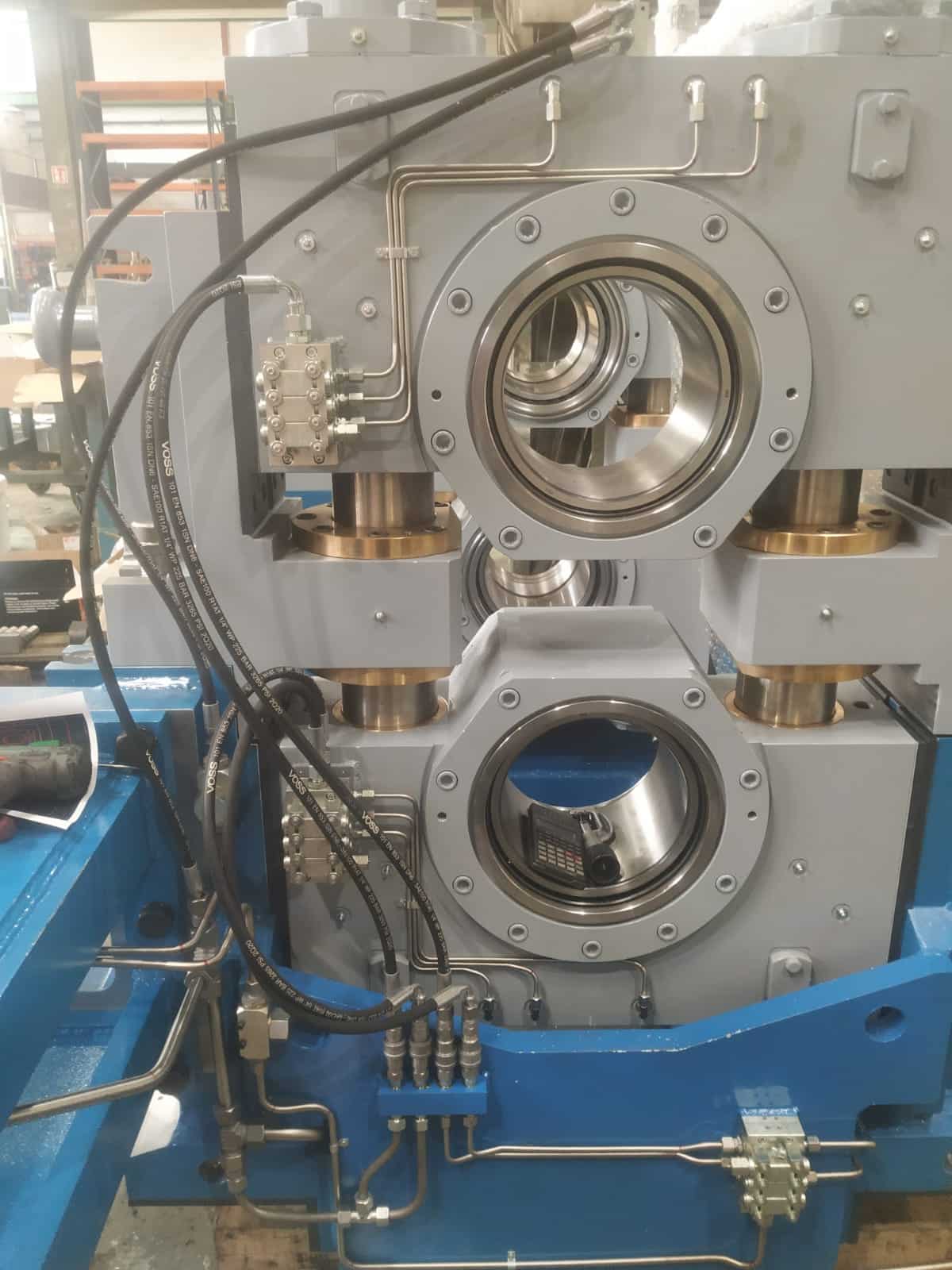

This system combines high-efficiency air-oil technology with a robust and flexible architecture capable of being installed into any rolling mill, regardless of speed, load or environmental conditions.

Significantly improves bearing cooling, even in high-temperature applications or under extreme stress. This not only increases operational safety by preventing overheating and unexpected failures, but also drastically reduces the need for maintenance.

Airotek incorporates an intuitive HMI that provides total control over lubrication: it allows you to view each cycle, adjust parameters in real time, and monitor system performance with complete traceability.

Airotek not only optimises the service life of critical components, but also enhances the overall performance of the production line by providing a modern, safe and adaptable solution to the current demands of the steel industry.

- improved cooling

- Lubrication control

- Adaptability to old rolling mills

Get your ROI in a year

The drastic reduction in lubricant consumption, by working with small quantities dispensed with pressurised air, eliminates the excessive expenditure typical of grease and represents continuous savings month after month.

At the same time, improved cooling and precise lubrication significantly extend the service life of bearings, reducing costly replacements and production downtime.

Water treatment plants also reap benefits. By preventing spills, contamination and lubricant waste, penalties, clean-up costs and environmental management costs are reduced.

All this is complemented by a significant reduction in maintenance hours, as the system requires fewer interventions and offers cleaner and more stable operation.

The combination of these factors makes the return on investment rapid, measurable, and fully justifiable from the first year of operation.

- Reduction in lubricant consumption

- Longer bearing life

- Benefits in water treatment plants

- Less maintenance required