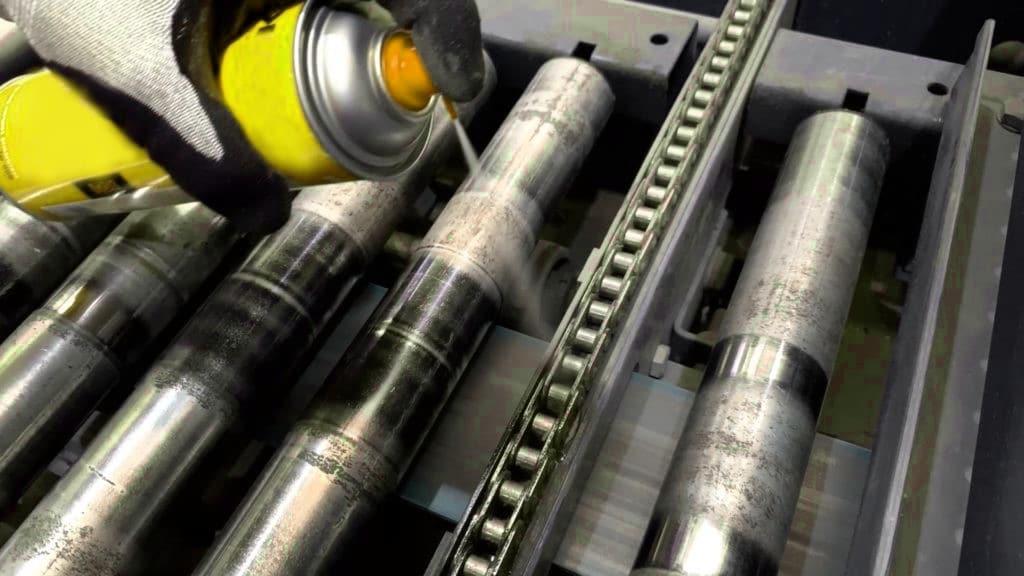

Best lubrication solutions for the Iron and Steel industry

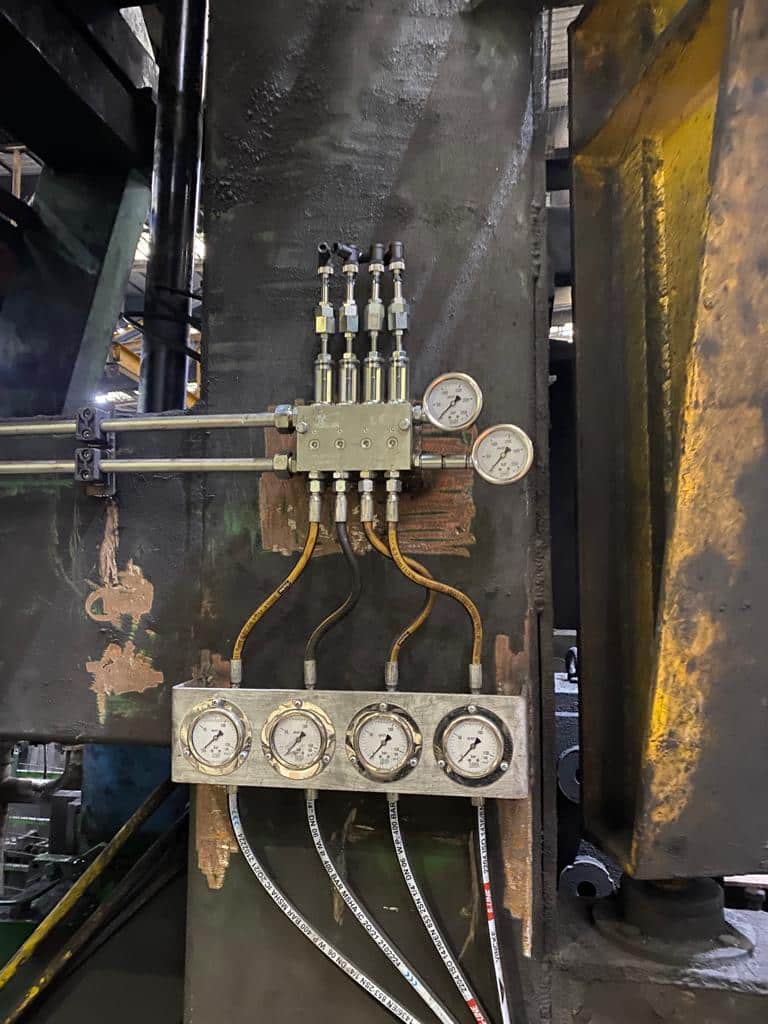

The iron and steel industry is a fundamental pillar of world economic development, producing essential materials for various sectors. In this context, proper lubrication becomes a critical factor to ensure the efficiency and longevity of machinery and equipment used in manufacturing processes.