NORTEK signs an important order for the Chinese paper industry

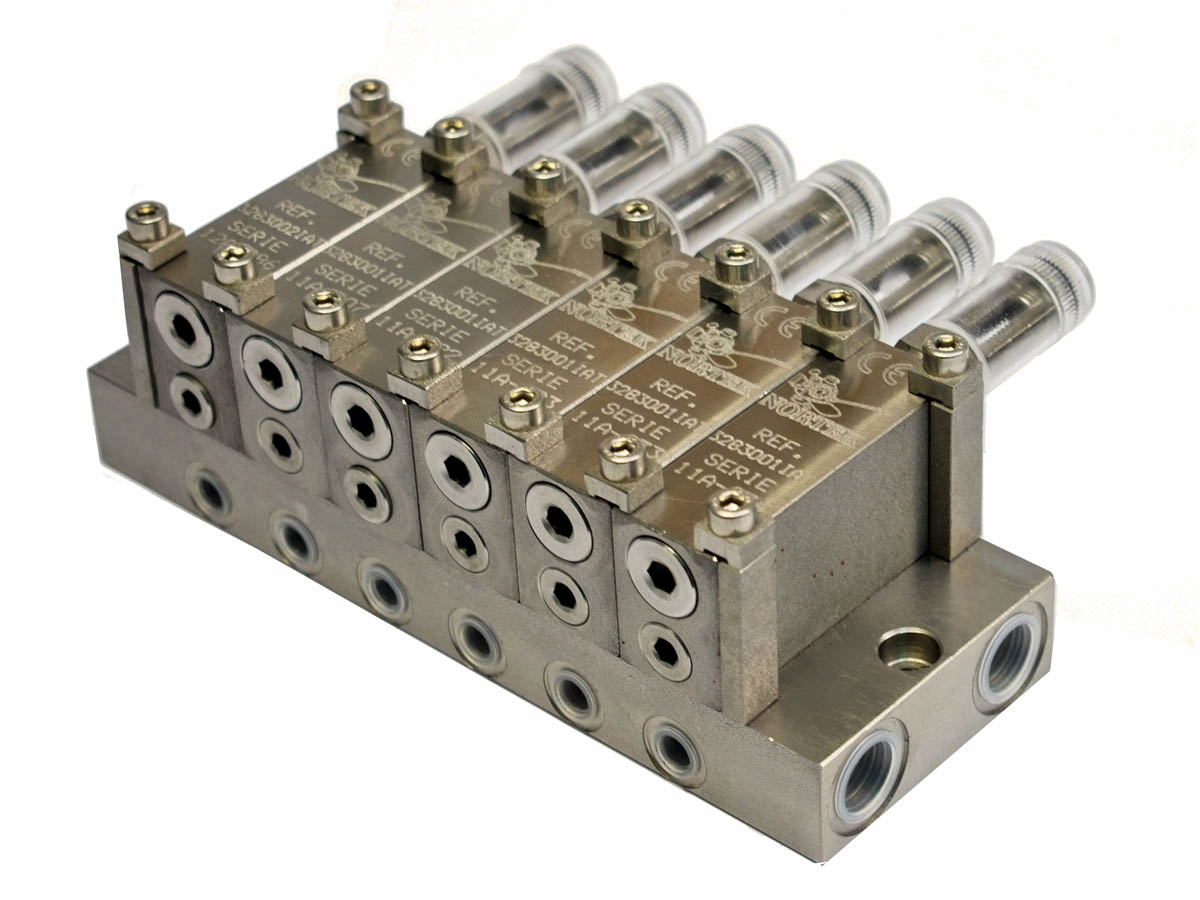

Our company recently signed an important supply contract for the Chinese paper industry that will result in the production of an extraordinary series of modular grease dosing valves, designed by NORTEK and manufactured and tested entirely in our production plant. Due to the distinct characteristics of the plant of destination, where the environmental working conditions are highly corrosive, all modular valves will be supplied, obviously, in stainless steel.

NORTEK’s modular dosing valves are a cutting-edge product due to their versatility, easy maintenance and proven reliability.

NORTEK modular dosing valves offer many advantages to our customers. Their flexible configuration, with removable turrets on a baseplate, makes them highly adaptable to any type of installation, since different injection volumes may be combined in the same block, favoring the most logical greasing at each point according to needs. Easy assembly and disassembly of turrets —by means of screws— allows them to be changed without altering the rest of the installation, which facilitates maintenance and leaves open the possibility of increasing or decreasing specific volumes easily through timely replacements of the turrets. All of our dosing valves are also individually tested and adjusted to the micron in the assembly of pistons, which ensures total reliability and neutralizes any risk of leakage.

This order highlights in particular the production capacity of our machining and precision workshops. The particular complexity involved in the machining of stainless steel is a common challenge for our technicians. In fact, all our grease, oil and air/oil dosing valves are offered either in carbon steel or stainless steel, at the customer’s choice.