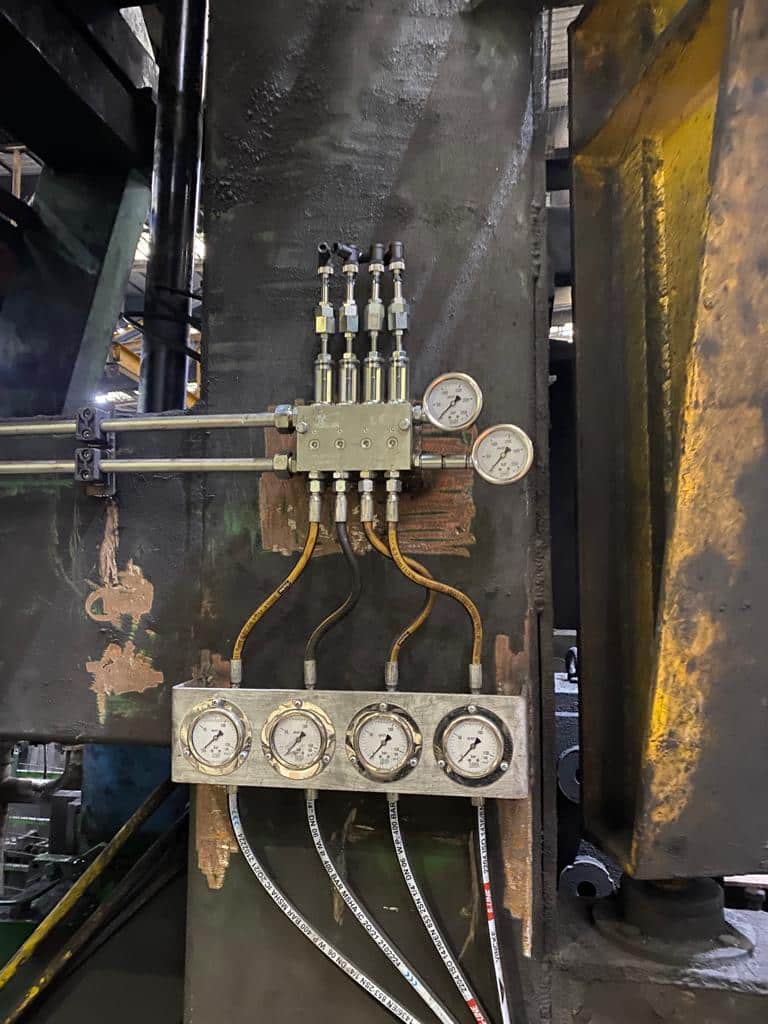

Nortek completes the manufacture of a large project for five MAGCLEAN magnetic separators

After several months of planning, design, and manufacturing, Nortek completes a large order for five magnetic separation oil filtration units requested by a major customer in the American steel industry.